Contact Info

- Nodka Europe Luchthavenweg 81 Room 038 5657 EA Eindhoven The Netherlands Email: [email protected]

- Nodka Europe Luchthavenweg 81 Room 038 5657 EA Eindhoven The Netherlands Email: [email protected]

Automation PC for Motion Control

Meeting the Next-Gen Demands of Motion Control

The Challenge of High-Performance and High-Precision Motion Controllers

In modern industrial automation, the demands for motion controllers are not only for speed but also for high precision and flexibility. Industries like high-end CNC, robotics, and semiconductors require a controller that can deliver reliable, real-time control while also providing the flexibility to use advanced, high-level programming languages for complex algorithms. The challenge for motion controller OEMs, machine builders, and integrators is finding a single platform that can meet all these needs.

Discover how Nodka’s motion control solutions can power your CNC, robotics, and semiconductor applications

The Solution: Nodka NP-6133-L2 Automation PC

NP-6133-L2

Automation PC

The Nodka NP-6133-L2 is an industrial automation PC engineered to serve as this powerful and reliable hardware foundation. It is designed to be the central computing core for an embedded network motion controller, providing the performance and connectivity required for demanding applications.

- High-Performance CPU: The NP-6133-L2 supports high-performance Intel® Core™ 10th/11th generation CPUs with a TDP up to 65W, providing the processing power for complex motion algorithms and other high-load tasks.

- Extensive Network Interfaces: With six Intel Gigabit Ethernet (GbE) LAN controllers, the NP-6133-L2 is an ideal platform for managing multi-axis networks like EtherCAT, enabling high-speed communication and synchronization.

- Robust and Compact Design: The unit features a rugged aluminum-magnesium alloy chassis with modular design, allowing it to operate reliably in temperatures ranging from -20°C to 60°C. Its compact form factor and DIN-Rail mounting option make it easy to integrate into a control cabinet.

- OS Support: It supports multiple operating systems, including Windows and Linux, and is ready for real-time platforms like CODESYS.

- Customization and Branding: Nodka provides OEM/ODM services, allowing partners to have a product designed and branded specifically for their own brand, which helps in creating a unique product identity.

The Technology: From IPC to Real-Time Motion Controller

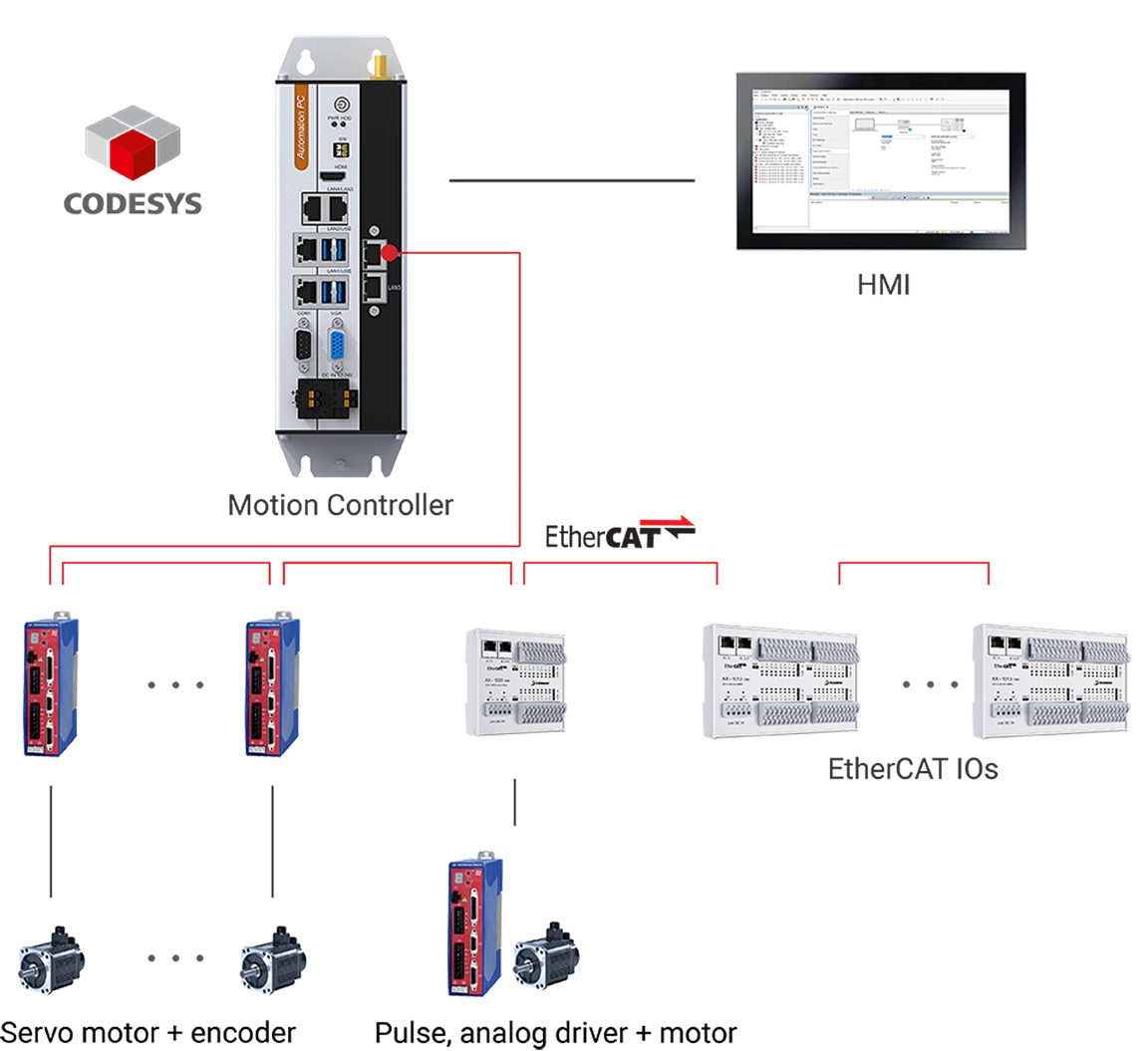

By integrating a software platform like CODESYS, the Nodka NP-6133-L2 is transformed from an industrial automation PC into a powerful Programmable Automation Controller (PAC). This synergy of hardware and software creates a next-generation solution for motion control.

- CODESYS as the Real-Time Kernel: The NP-6133-L2 provides the ideal environment for the CODESYS runtime system. With its optimized BIOS TCC Mode and support for a variety of operating systems, the IPC is primed to run the real-time application that is at the heart of a CODESYS-based motion controller.

- High-Level Language Support: To meet the need for flexibility, this platform can be programmed with standard IEC 61131-3 languages. Additionally, the platform allows for the integration of high-level languages like C/C++ to develop and embed custom libraries for advanced algorithms that require high precision or complex computations.

- EtherCAT Master Functionality: The multiple LAN ports on the NP-6133-L2 can be configured to act as an EtherCAT Master. This allows the CODESYS runtime to seamlessly manage high-speed, synchronized communication with all the connected EtherCAT servo drives and I/O modules, which is essential for high-precision applications.

Key Benefits

Nodka’s NP-6133-L2 Automation PC offers engineers and system integrators a powerful, reliable platform for real-time motion control. With Intel® Core™ processing performance, EtherCAT master support, and CODESYS compatibility, it enables precise coordination of multi-axis systems while reducing reliance on traditional PLCs. Its industrial-grade design ensures durability in harsh environments, while modular expansion options provide the flexibility to integrate field I/O, motion cards, or additional connectivity as needed. This combination of high performance, openness, and scalability makes the NP-6133-L2 an ideal foundation for CNC machines, robotics, packaging lines, and other advanced automation applications.

Ready to take your motion control system to the next level? Contact Nodka to learn how our Automation PC can deliver real-time performance for CNC, robotics, and multi-axis automation applications, or explore our full portfolio of industrial PCs and HMIs to find the right fit for your project. Get in Touch with Our Team