Contact Info

- Nodka Europe Luchthavenweg 81 Room 038 5657 EA Eindhoven The Netherlands Email: [email protected]

- Nodka Europe Luchthavenweg 81 Room 038 5657 EA Eindhoven The Netherlands Email: [email protected]

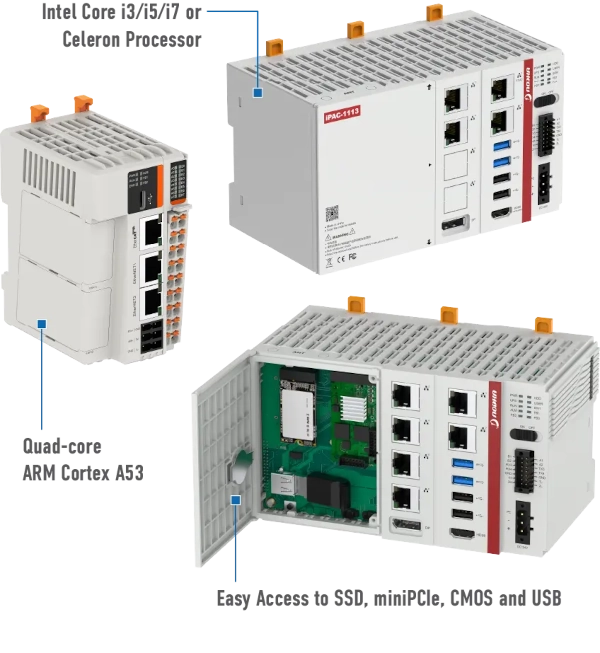

iPAC IPC Controllers and Modular IO for Industrial Automation

Flexible. Scalable. Industrial-Grade.

Scalable Control Platform to Make Your Machines Smarter

Nodka’s iPAC IPC Controller and IO Module Series is engineered for the next generation of industrial automation. Combining high-performance computing with modular EtherCAT-based IO expansion, the iPAC series empowers engineers, system designers, and OEMs to build smart, connected control systems, faster and more reliably than traditional PLC architectures.

Whether you’re replacing legacy PLCs, developing CNC or robotics controllers, or designing distributed automation solutions, iPAC offers the scalable control platform to make your machines smarter, your systems more integrated, and your development cycle more efficient.

Discover how Nodka’s solutions can transform your machines.

Key Features of the iPAC IPC Series

Compact, Industrial PC-Based Controllers

Available in both Intel x86 and ARM-based configurations, iPAC controllers deliver robust computing power in a DIN-rail-mountable, compact chassis. Designed for harsh industrial environments, they feature wide temperature support, anti-vibration design, and EMC compliance.

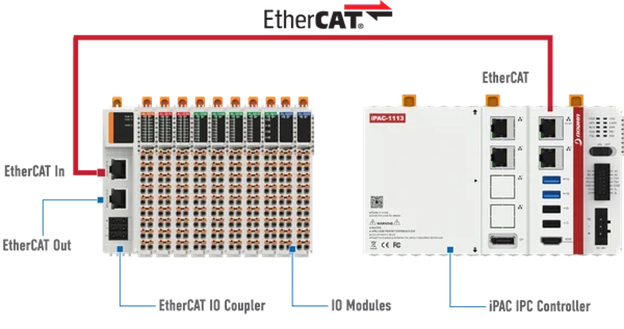

Modular EtherCAT IO Expansion

Built around a high-speed EtherCAT backbone, iPAC supports a wide range of IO modules—digital, analog, encoder, and temperature, through modular couplers and E-BUS connectivity. This makes system design more flexible, compact, and cost-effective.

Real-Time Automation & Motion Control

Compatible with leading automation software platforms including CODESYS, TwinCAT 3, PLCnext, Straton, and LogicLab, the iPAC enables real-time control for motion, CNC, robotics, and industrial IO synchronization.

Flexible Software & OS Support

With support for Windows and popular Linux distributions (Ubuntu, Debian, CentOS), the iPAC series is software-agnostic and compatible with both traditional and open industrial architectures.

Super Capacitor UPS for Data Protection

Every iPAC unit integrates a super capacitor-based UPS system that provides up to 10 seconds of full-load backup during power failure—preventing data loss and supporting reliable system recovery.

Use Cases in Industrial Automation System Integration

PLC Replacement for Production Line and Smart Machines

CNC and Machine Tool Integration

Use iPAC as the core controller for CNC systems with advanced IO and edge processing capabilities. Supports modern visualization and software logic frameworks for machinery control.

Motion and Robotics Controllers

Leverage real-time EtherCAT, versatile IO, and high-speed communication to build synchronized multi-axis motion and robotic systems.

OT-IT Convergence at the Edge

With native Ethernet support, modular IO, and real-time OS compatibility, iPAC serves as a gateway between factory floor operations and enterprise-level systems—ideal for Industry 4.0 environments.

Questions?

Whether you’re designing industrial control systems, upgrading machine automation, or enabling real-time robotics, Nodka’s iPAC IPC Controllers offer the perfect combination of power, modularity, and flexibility. Backed by EtherCAT IO scalability, a rugged industrial design, and support for industry-leading software platforms, iPAC is the future-ready platform for industrial automation system integr ation.

Explore the full iPAC Product Series — including technical specs, model options, and application guides.

We would be delighted to meet you and discuss how our solutions can support your upcoming projects. To learn more about our customization and OEM/ODM services, please contact us.

iPAC IPC controller series and EtherCAT IO module family

Related Products

Get In Touch

Yes, we can customize your products

+31(0) 40 785 1360

+86 2164940909

909-594-7630

Mon-Fri 9:00 AM - 5:00 PM CET

Mon-Fri 9:00 AM - 5:00 PM PST

Mon-Fri 9:00 AM - 5:00 PM PST