Step-by-Step Guide: Configuring an EtherCAT Controller with CODESYS on an IPC

Building a Real-Time Control System

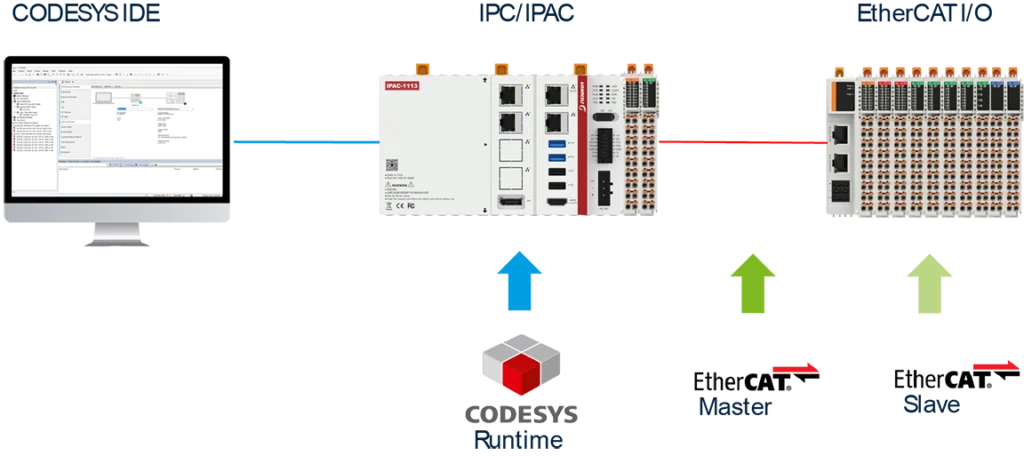

In modern industrial automation, there is a fundamental shift away from traditional, proprietary control systems to flexible, PC-based solutions. This new approach combines the power of an Industrial PC (IPC) with the flexibility of an open software platform to create a powerful, real-time motion controller. This guide will provide a clear, step-by-step walkthrough for configuring an EtherCAT master controller example on a Nodka iPAC series IPC with real-time optimized BIOS using CODESYS. The objective is to show how to install and configure CODESYS and make IPC into a high-performance, real-time controller.

Prerequisites: What You’ll Need

To follow this guide, you will need the following hardware and software:

-

- Hardware: A IPC (Nodka iPAC in this demonstration), EtherCAT-enabled devices such as servo drives and I/O modules, and Ethernet cables.

-

- Software: The CODESYS Development System installed on a host PC and the CODESYS Control runtime system installed on the iPAC IPC.

-

- Device Descriptions: Device description files (.XML) for your specific hardware (Nodka iPAC I/O modules in this demonstration), which are provided by the hardware manufacturer.

Step-by-Step Guide

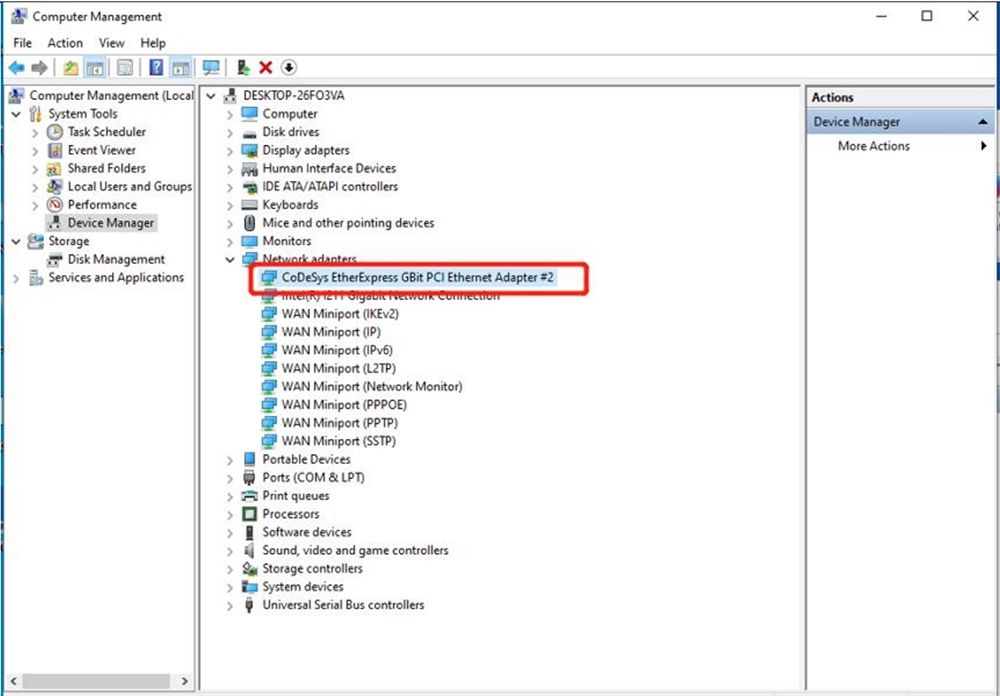

Step 1: Installing the Real-Time Ethernet Driver

The first and most critical step is to enable your IPC to act as an EtherCAT Master. This is done by installing a CODESYS-specific real-time Ethernet driver. This driver allows the CODESYS Control runtime to bypass the standard operating system’s network stack and gain direct, reliable access to the network controller on the hardware. In the CODESYS IDE, you will select the physical network card on the IPC that you want to dedicate to the EtherCAT bus.

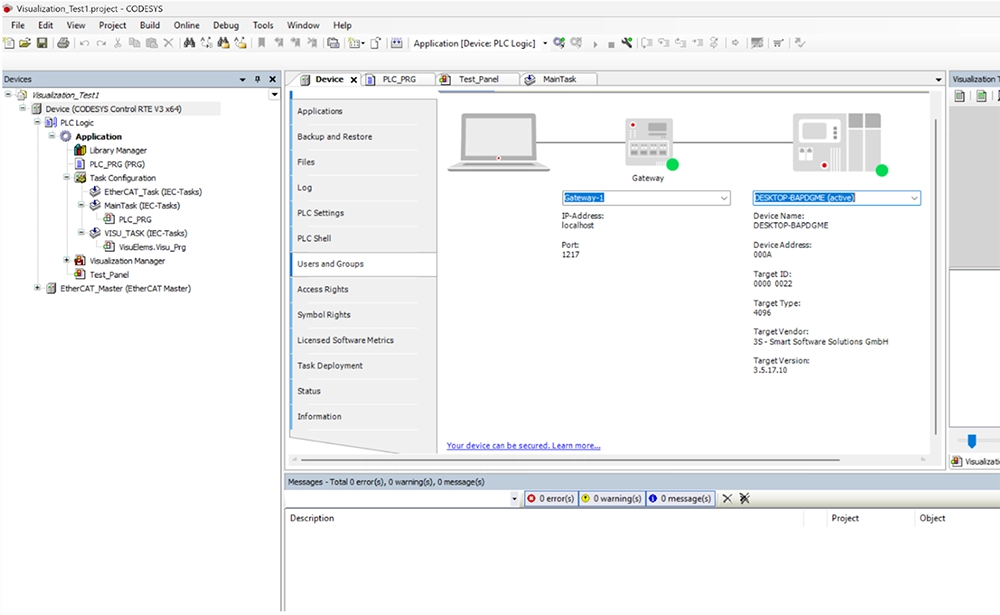

Step 2: Creating the Project

With the driver installed, you can now set up your CODESYS project.

-

- Connect the CODESYS Development System on your host PC to the IPC via Ethernet.

- Create a new project in the CODESYS IDE.

- Configure the target device, selecting the Nodka iPAC as the controller.

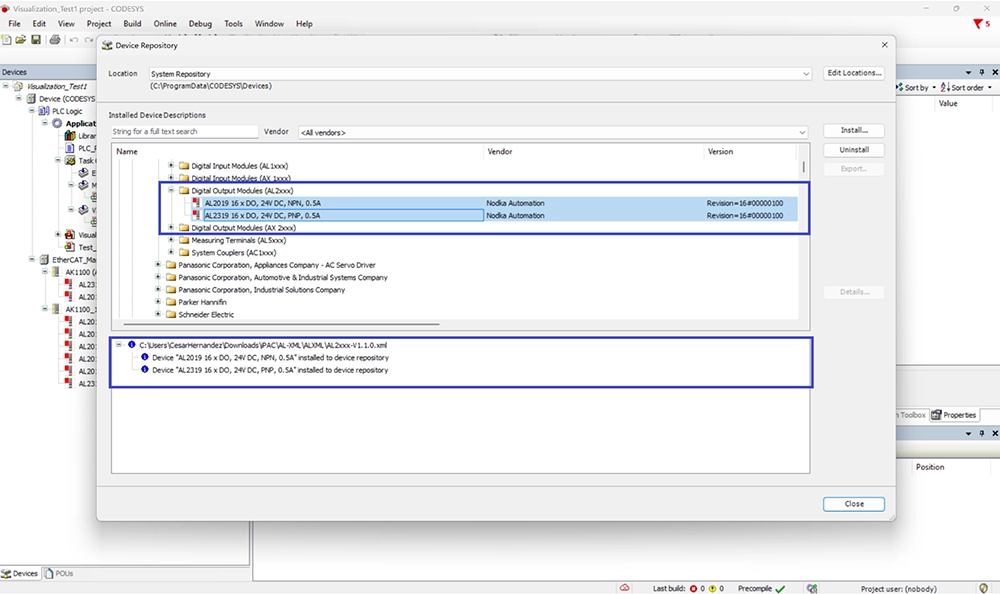

Step 3: Importing Hardware Descriptions

Before you can add your hardware to the project, you must first provide CODESYS with the hardware’s “digital blueprint”. Nodka provides this in the form of .XML files.

-

- Import these .XML files into the CODESYS device repository.

- This gives CODESYS all the information it needs to correctly configure and communicate with the attached modules and drives.

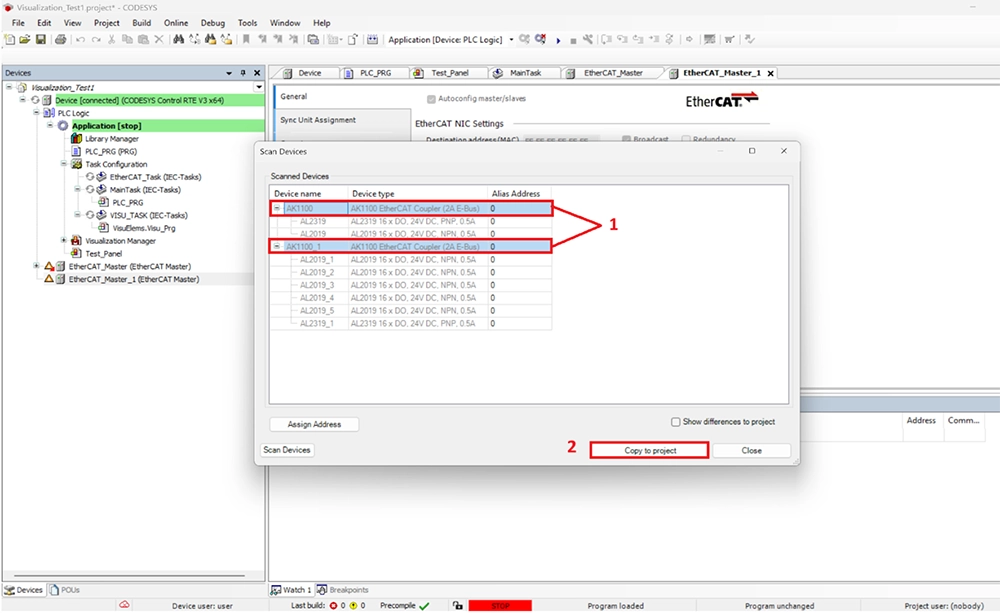

Step 4: Device Discovery

The flexibility of CODESYS and EtherCAT allows for automatic device discovery, which simplifies network configuration.

-

- Add the EtherCAT Master object to your project’s device tree.

- Use the “Scan for Devices” command. CODESYS will automatically detect all EtherCAT slaves connected on the network, such as your modular I/O and servo drives.

- The detected devices are added to your project’s device tree, creating a perfect digital representation of your physical hardware setup.

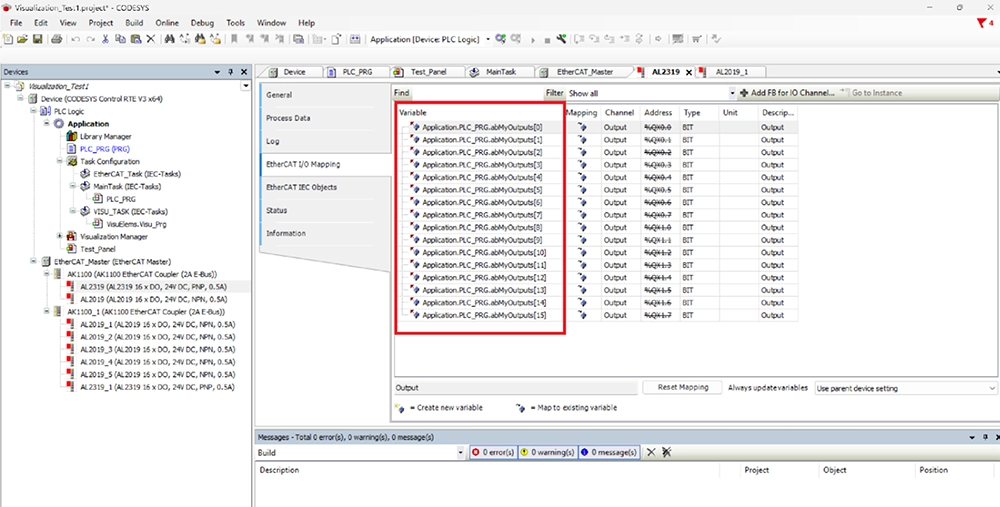

Step 5: I/O Mapping

With all devices discovered, you can now link the physical world to your program logic.

-

- In the I/O mapping table, assign program variables to the inputs and outputs of each module.

- This creates a direct connection between the state of your machine’s sensors and the variables in your CODESYS program.

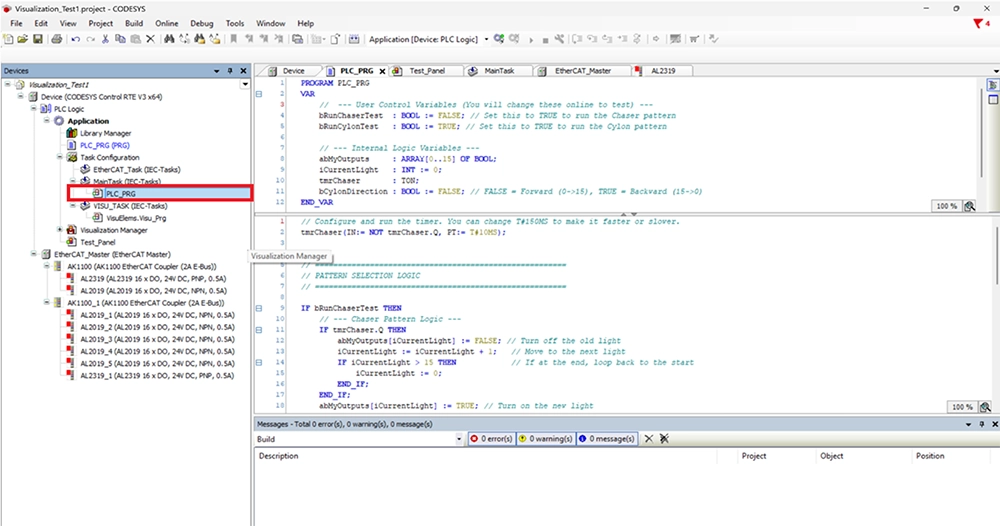

Step 6: Programming the Motion

The final step is to write the control logic and motion programs.

- Use the standardized IEC 61131-3 languages.

- For motion control, use the pre-built function blocks from the PLCopen Motion Control libraries. For example, MC_MoveAbsolute can be used to command a servo drive to move a robot to a specific position. The real-time optimizations of the Nodka iPAC ensure these commands are executed with high precision.

The Integrated Advantage

The power of this solution lies in the synergy between a purpose-built IPC and the CODESYS software ecosystem, which creates a powerful and open solution for next-generation automation. This integrated advantage offers significant benefits, including simplified deployment and reduced engineering effort. Ultimately, this approach provides a flexible, high-performance system for real-time control, which is essential for demanding industrial applications.

Ready to put this into practice?

This step-by-step guide is just the beginning. For deeper insights and additional examples, download our full CODESYS on iPAC IPC User Guide and review the CODESYS Tech Talk 2025 presentation for detailed walkthroughs and best practices. If you’d like to discuss your application or get support for deploying CODESYS on Nodka IPCs, reach out to our team at [email protected] .